Products

PRODUCT CENTER

GPPS Sheet Extrusion Line

Category:

Keywords:

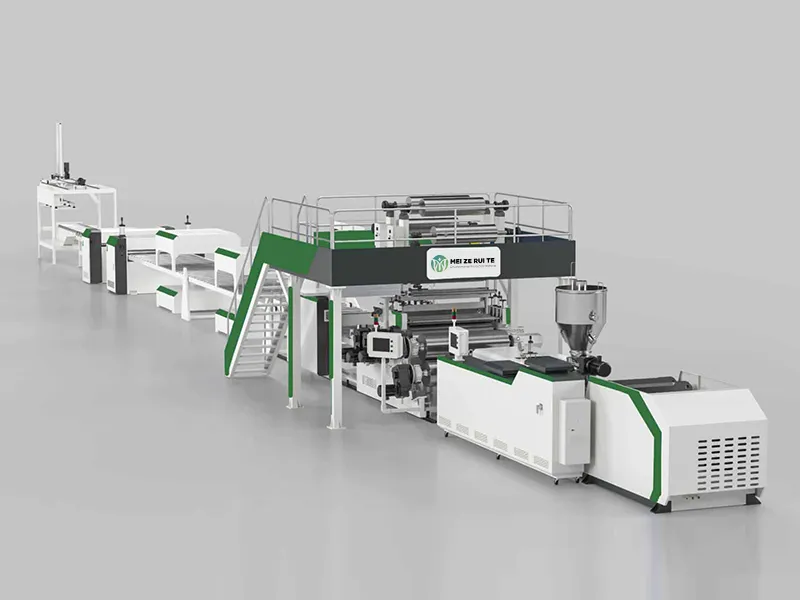

GPPS Sheet Extrusion Line

- Description

-

- Commodity name: GPPS Sheet Extrusion Line

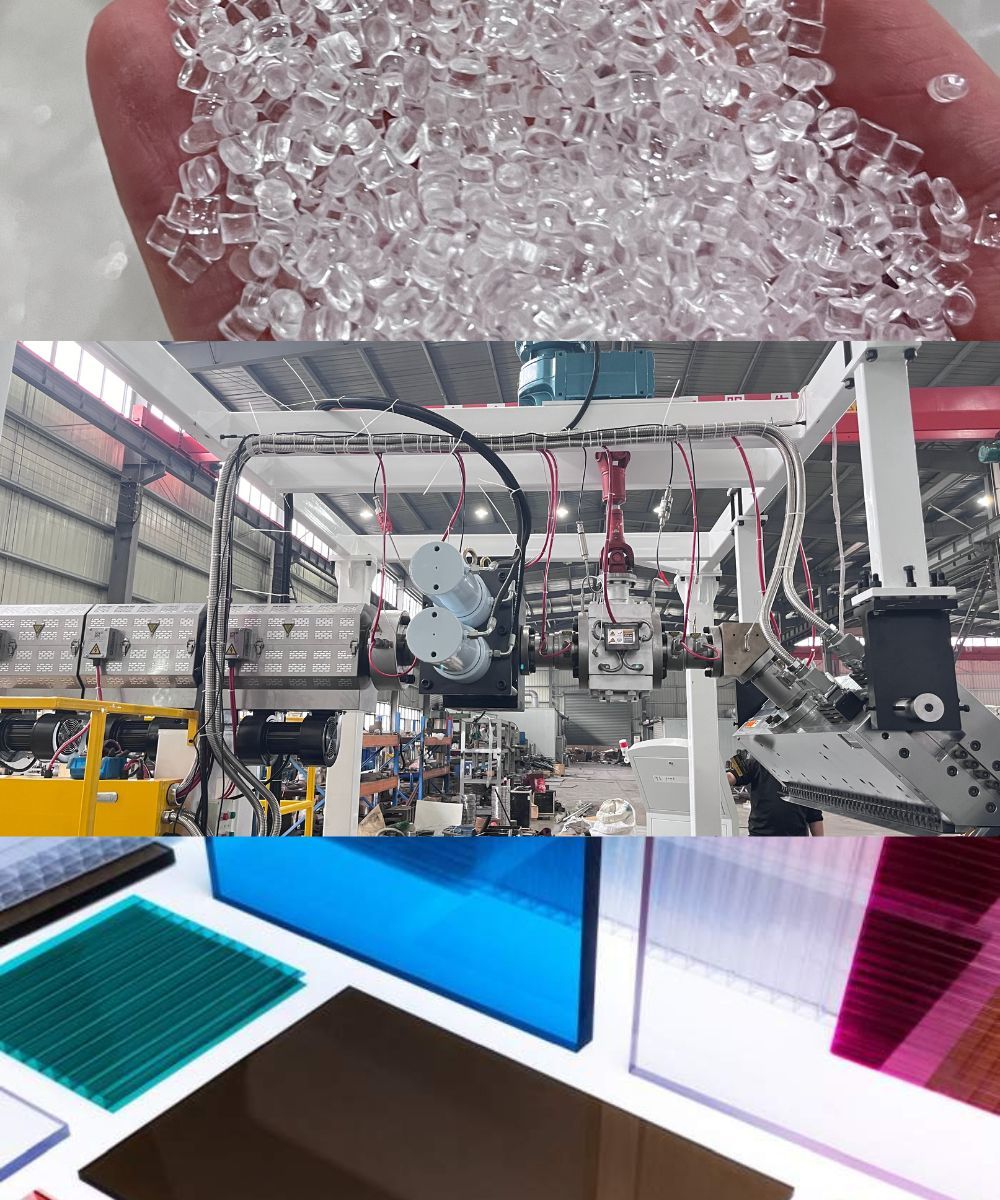

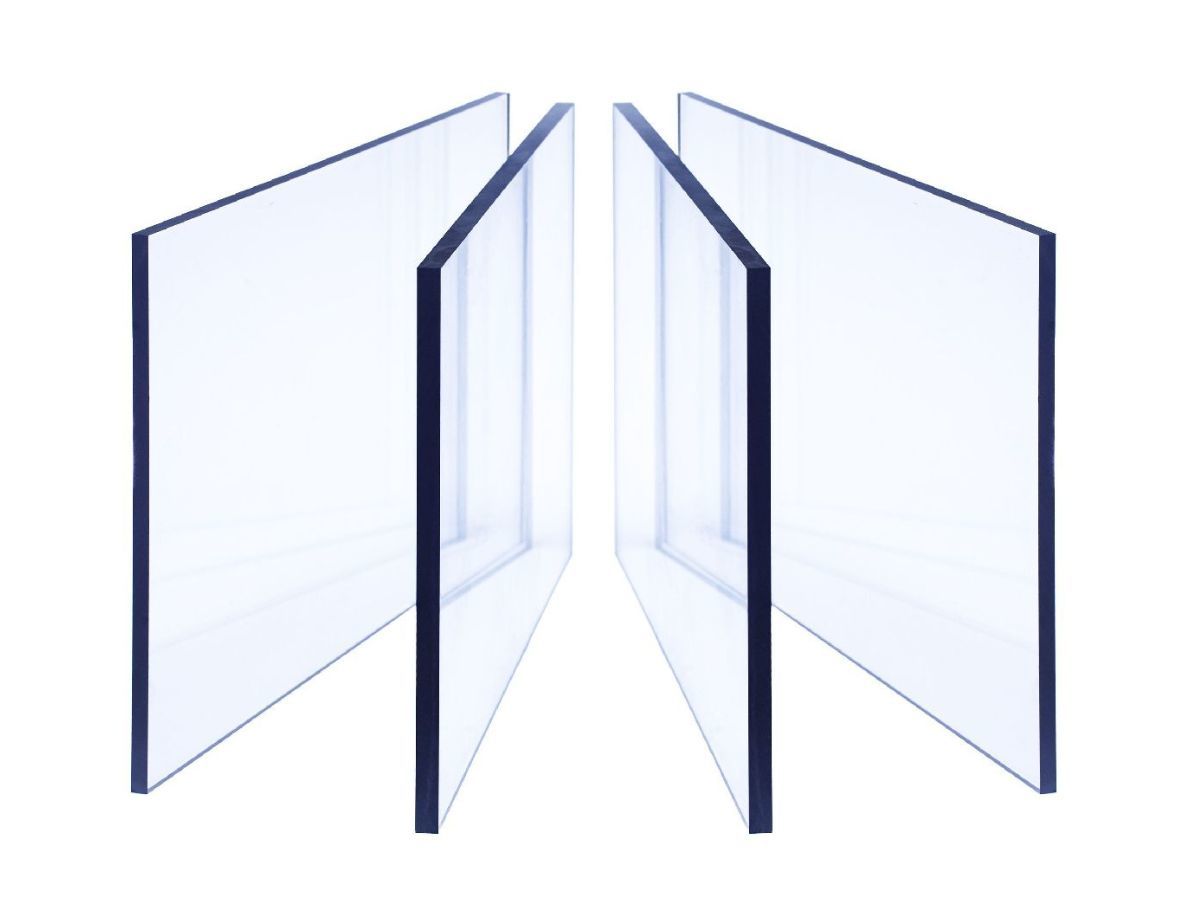

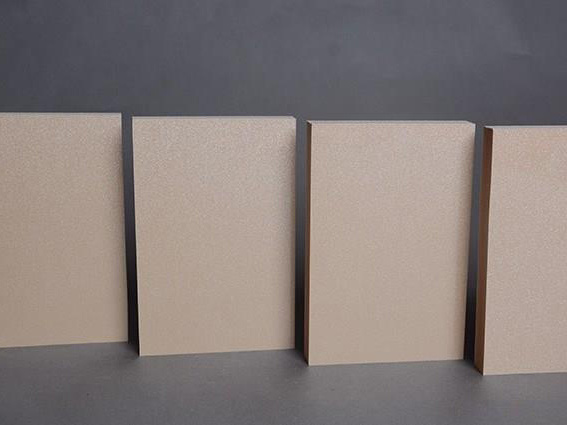

GPPS Sheet Extrusion Line is a high-performance manufacturing system designed for the production of GPPS Sheet with exceptional purity, gloosy and no crystal point.

Applications and Features of GPPS Sheet Extrusion Line

GPPS Sheet Extrusion Line is a high-performance manufacturing system designed for the production of GPPS Sheet with exceptional purity, gloosy and no crystal point.

Key Features of the Production Line:

1.Advanced Extrusion Technology: Our GPPS Sheet Extrusion Line employs state-of-the-art extrusion equipment to ensure uniform thickness, smooth surfaces, and no bubbles.

2.High Efficiency and Automation:The production line integrates automation systems, including precise temperature control and synchronized operations, enhancing productivity and reducing labor costs.

3.Customizable Design:Our production line supports various sheet specifications, including thickness, width, and surface textures, to meet diverse application needs.

4. Precise cutting system:We adopts knife cutting and braking system together to reach perfect edge trimming and cross cutting. Non-dust cutting system which makes workshop more clean and energy saving.

5.Easy Operation and Maintenance:The user-friendly interface and robust construction ensure ease of operation and maintenance, reducing downtime and operational costs.

GPPS Sheet Production Line Workflow

Material Feeding

Raw materials GPPS pellets are fed into the hopper of the extruder by vacuum loader and hopper dryer. The feeding system ensures precise measurement and continuous supply for uninterrupted production.

Extrusion and Melting

The extruder heats and melts the raw materials while mixing them evenly. The screw rotation ensures homogeneous material flow and prepares it for shaping.

Shaping and Surface Finishing

The melt material is extruded through a die head to form a flat sheet. It is then passed through calender rollers to achieve uniform thickness and the desired surface finish, such as glossy or matte or embossing.

Cooling and Laminating (Film Coating)

The sheet is cooled using water and air both cooling system to stabilize its structure. After cooling, a protective film is laminated onto the surface to prevent scratches during handling.

Cutting and Edge Trimming

The cooled sheet is cut to the desired length using a cutting machine. Simultaneously, excess edges are trimmed to ensure uniformity and precise dimensions.

Automatic stacking

The cut plates are neatly stacked on pallets using automated robots.

Characteristics and applications of GPPS Sheets

Characteristics of GPPS plastic:

GPPS is colorless, odorless, tasteless, shiny, transparent particles. It is light, cheap, has low water absorption, good colorability, dimensional stability, good electrical properties, transparent products, and easy processing.

Application of GPPS plastic:

General-purpose polystyrene can be used in daily necessities, electrical appliances, instrument housings, toys, lamps, household appliances, stationery, cosmetic containers, indoor and outdoor decorations, fruit plates, optical parts (such as prisms, lenses), lens windows and moldings, car lights, telecommunications accessories, electric frequency capacitor films, high-frequency insulation materials, TV containers, waveguides, chemical containers, etc. Suspension polymer resins can be made into foam plastics of different densities, used as insulation, sound insulation, shockproof, floating, packaging materials, cork substitutes, pre-foamed bodies can be used as water filtration media and to prepare lightweight concrete, and low-foamed plastics can be made into synthetic wood for furniture, etc.

Previous

Application

Logistics & Payment

FAQ

Q: How soon can I get the quotation?

A: We will make you an offer within 12 hours of receiving your ineuiry.

Q: Can I buy samples placing orders?

A: Yes,The sample is free.

Q: Do you provide OEM services?

A: Yes,we can produce under your own brand name.

MORE PRODUCTS

PVC Additives

PVC Heat Stabilizer

PVC Processing Aid

-

MBS Impact Modifier

The pvc foaming regulator is also an acrylic processing aid, which has all the basic characteristics of the pvc processing aid, the only difference with the pvc general processing aid is the molecular weight, the molecular weight of the pvc foaming regulator is much higher than the general processing aid.

-

PVC Foaming Regulator

The pvc foaming regulator is also an acrylic processing aid, which has all the basic characteristics of the pvc processing aid, the only difference with the pvc general processing aid is the molecular weight, the molecular weight of the pvc foaming regulator is much higher than the general processing aid.

PVC Foaming Agent

-

AC Foaming Agent For WPC Floor

These products appeared light yellow powder, has the nature of stable quality, convenient for transportation and no special restrictions when export cargo.

-

AC Foaming Agent For PVC Foam Board

These products appeared light yellow powder, has the nature of stable quality, convenient for transportation and no special restrictions when export cargo.

PVC Lubricant

-

PVC Inner And External Lubricant

Inner lubricant I-60 is a neutral saturated aliphatic alcohol dicarboxylic acid ester. Its character is milky or pale yellow flake or flowing powder, non-toxic and tasteless, insoluble in water, soluble in tributyl phosphate and chloroform, melting point 42-48℃, flash point> 225℃

-

PE WAX Lubricant

white flake or white powder, with high softening point, low viscosity, large molecular weight, and small heat loss. Strong external lubrication, delayed plasticization, reduced torque.

Titanium Dioxide

-

Rutile Titanium Dioxide

Titanium dioxide is used as a coloring agent in the rubber industry, but also has reinforcing, anti-aging and filling effects. Titanium dioxide is added to white and colored rubber products.

-

Anatase Titanium Dioxide

Anatase titanium dioxide is an excellent white powder pigment, which has good light scattering ability, so it has good whiteness, high coloring power, strong covering power, high chemical stability and good weather resistance, non-toxic and tasteless, no stimulation to human body.

Fluorescent Whitening Agent

PVC Wood Plastic Special Pigment

-

Toner For PVC Wood Plastic

The toners, used for indoor and outdoor series with stable quality, strong sense of wood, high saturation, small color difference between batches, easy to use.

-

Masterbatch For PVC Wood Plastic

Stable quality of wood-plastic particles-source control of raw materials, strict control during production, comparison of sample retention, leaving the factory after passing the test.

Foaming Agent Series

-

High-end Ultra-light Foaming Agent For Injection Molding Shoe Materials - Endothermic Balance Type

The endothermic and exothermic balance type white foaming agent developed and produced by our company has the advantages of good narrow decomposition temperature characteristics

-

Low Temperature Foaming Agent-acp Series

ACP-W (low temperature foaming agent) is made of foaming agent AC, DPT and other main functional additives through scientific ratio and systematic verification, and is manufactured by reaction process. The product does not contain toxic polymerization such as lead and cadmium. It can quickly decompose at lower temperature, significantly improve the whiteness of foamed products, and make it have good tensile strength, tear strength, elongation at break and uniform and dense cell structure.

-

Foaming agent-white foaming agent NC series

The company's ADC yellow foaming agent is used in foaming materials, which can form independent spherical bubble cells and form a three-dimensional structure similar to honeycomb, so that the material can obtain better mechanical strength.

-

Foaming agent-yellow foaming agent ADC series

The company's ADC yellow foaming agent is used in foaming materials, which can form independent spherical bubble cells and form a three-dimensional structure similar to honeycomb, so that the material can obtain better mechanical strength.

Sheet/Film Solution

-

SPC Flooring Production Line

The SPC flooring production line developed by our company is suitable for extruding SPC flooring of various sizes. We also provide customers with formulas and related technologies to help customers complete their projects.

-

GPPS Sheet Extrusion Line

GPPS Sheet Extrusion Line is a high-performance manufacturing system designed for the production of GPPS Sheet with exceptional purity, gloosy and no crystal point.

-

PC ABS Sheet Extrusion Line

The loader transports PC and ABS raw materials into the extruder’s hopper. The system ensures a continuous, stable material feed, reducing manual intervention and enhancing efficiency. Sensors monitor the material levels to prevent interruptions.

-

PMMA Acrylic Sheet Production Line

Acrylic Sheet Production Line is a high-performance manufacturing system designed for the production of acrylic sheets with exceptional purity, gloosy and no crystal point.

-

HIPS Sheet Extrusion Line

Based in our stragtic cooperation with core components supplier and our own designs, we established a very strong system whatever in technology, machine quality stability and supplying capacity. With many successful cases we have supplied whatever in China local market or foreign market.

-

PVC/WPC Foam Board Extrusion Line

PVC/WPC Foam Board Extrusion Line is also called PVC foam board production line, foam board making machine. Our PVC foam board making machine includes the special Twin-screw extruder, mould and other auxiliary machines.

-

PVC Free Foam Sheet Extrusion Line

This PVC free foam sheet extrusion line can be used to produce PVC free foam sheet, which consists of Conical twin screw extruder, T-Die, three roller calender, cooling frame, tractor,cutting machine and stacker.

-

LVT Flooring Production Line

The traditional LVT floor has complex production process, high energy consumption, long labor time, and is not conducive to environmental protection.

Profile Solution

-

PVC Cellular Foam Profile Extrusion Line

PVC Cellular Foam Profile is a product with solid wood characteristics made of solid PVC synthetic material through high-tech extrusion equipment.

-

PVC Siding/Soffit Panel Production Line

This PVC siding/soffit panel production line is also called: PVC siding/soffit panel extrusion line,PVC siding/soffit panel making machine, vinyl siding extrusion line, PVC vinyl siding production line, PVC vinyl siding making machine, PVC vinyl siding exterior wall cladding extrusion line, vinyl siding trim machine, vinyl extrusion equipment, vinyl extrusion machinery and etc.

-

WPC Decking Production Line

This PVC siding/soffit panel production line is also called: PVC siding/soffit panel extrusion line,PVC siding/soffit panel making machine, vinyl siding extrusion line, PVC vinyl siding production line, PVC vinyl siding making machine, PVC vinyl siding exterior wall cladding extrusion line, vinyl siding trim machine, vinyl extrusion equipment, vinyl extrusion machinery and etc.

-

PVC WPC Door Frame Extrusion Line

PVC WPC Door Frame Extrusion Machine use PVC and Wood Powder Mixed Material, It can produce hollow type and solid type door frame profile. By changing moulds.

-

PVC Edge Banding Extrusion Line

PVC/ABS edge banding extrusion can be divided into two categories according to the production process: edge banding sheet production line and edge banding strip production line.

-

UPVC Window And Doors Profile Extrusion Line

Specialized conical twin screw extruder with unique screw design for high quality plaisitising of PVC materials to ensure produce high strengh of PVC window profiles.

-

PVC Ceiling Panel Extrusion line

PVC Ceiling Panel Extrusion Line is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

-

PVC/WPC Wall Panel Extrusion Line

Fluted PVC WPC wall panels are a versatile and stylish solution for enhancing the aesthetics and functionality of interior spaces. Made from durable PVC (polyvinyl chloride) material, these panels feature a unique fluted design that adds depth and texture to any wall surface.

-

PVC WPC Door Panel Production Line

The PVC/WPC door panel extrusion line is suitable for producing the both PVC and WPC door panel.We can provide the turnkey project for integrated door panel.

-

PVC WPC Profile Production Line

PVC WPC Profile Production Line is mainly used to produce various plastic profiles. This profile extrusion line has the advantages of stable plasticization, high output, low shear force and long service life in the process of producing plastic profile extrusion.

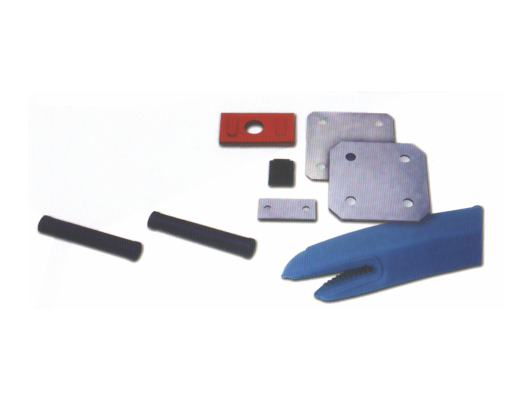

Silicone Rubber

-

MZ一TY Type

This product MZ-TY type: This product can be customized according to customer requirements of various hardness, different colors of silicone rubber, including molding, extrusion silicone rubber, etc. can also be vulcanized and colored for customers.

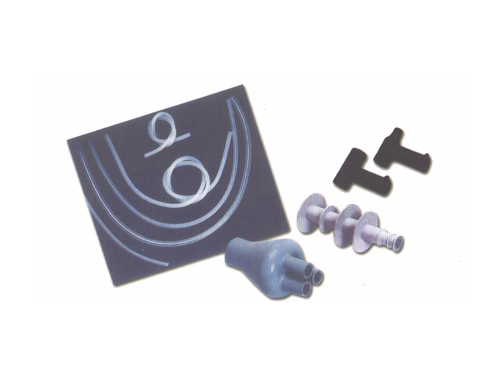

-

MZ一TR Type

This product: MZ-TR type: This product can be customized according to customers' requirements of high-permeability type, ordinary type; including gas-phase glue, etc.

-

MZ一JY Type

Mainly used for insulating materials, including power insulators, etc., can be customized according to customer requirements, etc.

-

MZ一ZR一01Flame Retardant Silicone Rubber

Mainly use flame retardant products, especially in new energy vehicle batteries to produce flame retardant sheets, to separate each battery

Glue Products

-

First wulcnization condition for test piece:175Cx5min

Physical and Mechanical Properties are based on first vulcanization data,Electrical Properties are drawn from secondvulcanization data.

-

Ceneral Purpose Fier Resisitant Silicone Rubber

Physical and Mechanical Properties are based on first vulcanization data,Electrical Properties are drawn from secondvulcanization data.

-

General Purpose V apour-phase Gum

First vulcnization condition for test piece:175Cx5min

-

General Purpose Silicone Rubber for Molding

First vulcnization condition for test piece:175Cx5min

-

High Temperature Resisitant Silicone Rubber

First vulcnization condition for test piece:175Cx5min

-

High Voltage Insulator

Physical and Mechanical Properties are based on first wulcanization data,Electrical Properties are drawn from secondvulcanization data.

-

Standard Silicone Rubber for Molding

First vulcnization condition for test piece:175Cx5min

-

Standard Silicone Rubber for Extrusion

Physical and Mechanical Properties are based on first vulcanization data.Electrical Properties are drawn from second vulcanization data.

-

Standard High Tear Resistance V apour-phase Gum

Physical and Mechanical Properties are based on first vulcanization data.Electrical Properties are drawn from second vulcanization data.

Plastic Products

Sheet Products

-

WPC Flooring

WPC floor ing is mainly made of fast-growing wood, adding biomass materials such as straw, and high pressure and high temperature processing after mixing. Advantages of WPC flooring. Moisture proof, waterproof, anti skid, moth proof, antiseptic and antibacterial . High environmental protection...

-

SPC Flooring

Advantages of SPC flooring: Green environmental protection, the main raw material is polyvinyl chloride, natural stone powder, no glue, no formaldehyde, benzene, no heavy metals and carcinogens, no radiation. S uper wear-resist ant , the wear resistance is 2-3 times of the laminate floor.

-

Plastic Wood Veneered Foaming Board

Products features: The surface of the product can be affixed with fireproof board, PVC film, aluminum plate,ect. The product has rich design and colors,and provide professional customization.

-

Plastic Wood Co-Extrusion Foaming Board

Product specifications: 1220 × 2440mm, colors can be customized according to customer requirements. lastic wood application: Overall cabinets, wardrobes, external wall hanging boards, floor substrates, decorative hanging boards, indoor doors, skirting lines , outdoor flooring, plastic wood...

-

PVC Co-Extruded Black Foam Board

Product thickness: 3-30mm Product specifications: 1220 × 2440mm, colors can be customized according to customer requirements. Product Usage: 1. Exhibitions, salons, shops, offices, banks, hotels, restaurants and apartments. 2. Building decoration materials, exterior and interior wall decoration,...

-

PVC Co-Extruded Blue Foam Board

Product thickness: 3-30mm Product specifications: 1220 × 2440mm, colors can be customized according to customer requirements. Product Usage: 1. Exhibitions, salons, shops, offices, banks, hotels, restaurants and apartments. 2. Building decoration materials, exterior and interior wall decoration,...

Profile Products

-

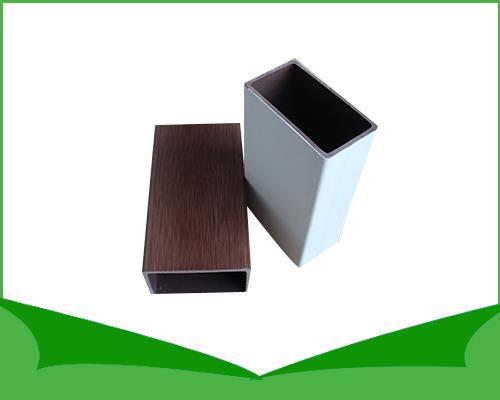

100×20mm

(1) Water-proof, moisture-proof and non-decaying by soaking in water. (2) With a natural sense of wood, color diversity does not fade. (3) Green and environmentally friendly, free of formaldehyde and other pollutants. (4) Automatically extinguish in case of fire, without producing toxic gas.

-

100×120mm

(1) Water-proof, moisture-proof and non-decaying by soaking in water. (2) With a natural sense of wood, color diversity does not fade. (3) Green and environmentally friendly, free of formaldehyde and other pollutants. (4) Automatically extinguish in case of fire, without producing toxic gas.

-

200×25mm

(1) Waterproof, moisture-proof and non rotten. (2) It has natural wood sense and wood texture, and custom color. (3) High environmental protection, pollution-free, pollution-free and recyclable. (4) High fire resistance. It will automatically extinguish in case of fire, and no toxic gas will be...

-

200×100mm

Waterproof, moisture-proof and non rotten.

-

600mm WPC Clad Integrated Wall Panel

(1) Waterproof, moisture-proof and non rotten. (2) It has natural wood sense and wood texture, and custom color. (3) High environmental protection, pollution-free, pollution-free and recyclable. (4) High fire resistance. It will automatically extinguish in case of fire, and no toxic gas will be...

-

450mm WPC Clad Integrated Wall Board

(1) Waterproof, moisture-proof and non rotten. (2) It has natural wood sense and wood texture, and custom color. (3) High environmental protection, pollution-free, pollution-free and recyclable. (4) High fire resistance. It will automatically extinguish in case of fire, and no toxic gas will be...

-

60mm Decorative Line And 32mm Fastening

60mm decorative line with 32mm fastener

-

80mm Decorative Line And 32mm Fastening

100mm Skirting Line and Matching Z Fastener

-

100mm Ceiling Line And Z Fastening

100mm Skirting Line and Matching Z Fastener

-

100mm Skirting Line And Matching Z Fastener

100mm Skirting Line and Matching Z Fastener

-

50mm×50mm Exterior Hollow Column

50×50 Exterior hollow column

-

50mm×90mm Exterior Hollow Column

50×90 Exterior hollow column

-

Outdoor Plastic Wood Fence

125mm×125mm Exterior hollow column

-

150mm WPC Co-Extruded Brushed Exterior Wall Panel

150mm plastic wood co-extruded brushed exterior wall panel

-

163mm Plastic Wood Brushed Exterior Wall Panel

163MM plastic wood brushed exterior wall panel

-

200mm WPC Co-Extrusion Wall

200mm plastic wood co-extruded brushed exterior wall panel

-

200mm WPC Wall Cladding

200mm Plastic Wood Co-Extruded Embossed Outer Wall Panel

-

200mm Plastic Wood Co-Extruded Embossed Outer Wall Panel

200mm Plastic Wood Co-Extruded Embossed Outer Wall Panel

-

Outdoor DIY Tiled Floor

PVC floor, outdoor plastic wood, outdoor wood plastic, garden plank floor, PVC plastic floor

-

140mm×20mm WPC Floor

PVC floor, outdoor plastic wood, outdoor wood plastic, garden plank floor, PVC plastic floor

-

90mm WPC Floor

PVC floor, outdoor plastic wood, outdoor wood plastic, garden plank floor, PVC plastic floor

-

140mm Circle Hollow WPC Decking

PVC floor, outdoor plastic wood, outdoor wood plastic, garden plank floor, PVC plastic floor

-

140mm×25mm WPC Co-Extrusion Decking

PVC floor, outdoor plastic wood, outdoor wood plastic, garden plank floor, PVC plastic floor

-

138mm×23mm WPC Co-Extrusion Decking

PVC floor, outdoor plastic wood, outdoor wood plastic, garden plank floor, PVC plastic floor

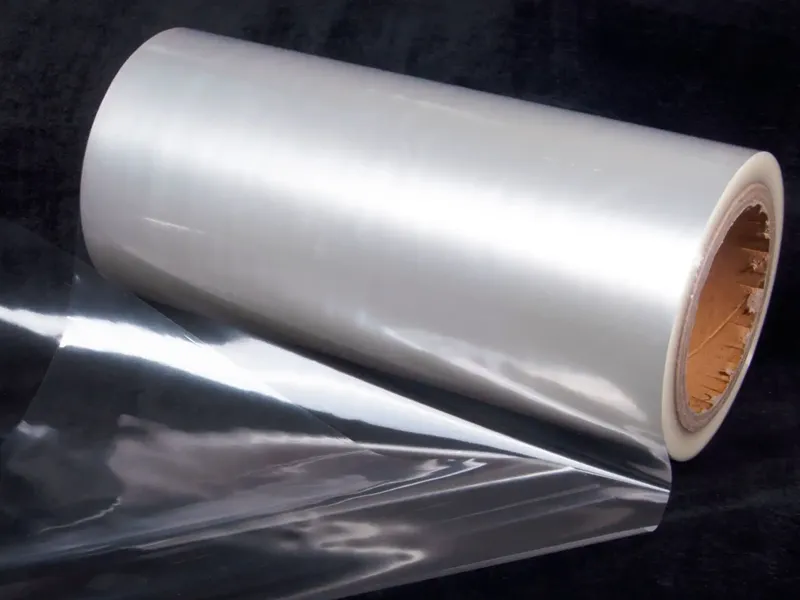

Film Products

-

ASA film

Our plastic film products mainly mainly include plastic wrap, packaging film, EVA POE film, PVC film, PP film, ASA film, PC film and other film products.

-

PP film

Our plastic film products mainly mainly include plastic wrap, packaging film, EVA POE film, PVC film, PP film, ASA film, PC film and other film products.

-

Plastic wrap

Our plastic film products mainly mainly include plastic wrap, packaging film, EVA POE film, PVC film, PP film, ASA film, PC film and other film products.

-

Packaging film

Our plastic film products mainly mainly include plastic wrap, packaging film, EVA POE film, PVC film, PP film, ASA film, PC film and other film products.

-

PVC film

Our plastic film products mainly mainly include plastic wrap, packaging film, EVA POE film, PVC film, PP film, ASA film, PC film and other film products.

PVC Product Technical

PVC Technical Know-How Package

PVC Formulation Optimization

MEIZERUITE

Leave A Message

If you are interested in our products, please leave your email.

CONTACT